WAXJET 400 PROVIDES:-

1. Customized and quick production of small batch orders.

2. Produce styles which traditional craft cannot achieve.

3. Save the cost of plate making and revision, reduce reliance on manual revision.

4. Standardized process and save labor cost.

5. Anti-leak style, release designers creative.

MATERIAL SPECIFICATION:-

| Structural Material | FFWJ1100 N.W.:3.0 kg/bottle (2 material bins/ each device, auto reloading) |

| Supporting Material | FFMS3100 N.W.:3.6 kg/bottle (2 material bins/ each device, auto reloading) |

PRODUCT SPECIFICATION:-

| Molding Method | MJP |

| Molding Size | 289*218*150mm |

| Printing Mode | XHD:1200*1200*1600 DPI:16μ of each layer |

| Dimensional Accuracy* | ±0.04mm / 20mm |

| Power Supply | 210-240VAC, 50Hz, single phase, 25A |

| Device Size | 1352*775*1600mm |

| G.W. | 630kg |

| Package Size | 1530*900*1837mm |

| Slicing Software | WaxJetPrint |

| Data Support Format | stl / slc |

| E-mail Notify | Applicable |

| Disk Capacity | 500G |

| Network Connection | Network 10/100/1000 ethernet / USB |

| Guest Operating System | Windows 7 / Windows 10 (64bit) |

| Operating Environment | 18-28℃, 30-70% of humidity |

| N.W | 480kg |

PRODUCT FEATURES:-

Advanced MultiJet Printing (MJP) Technology

The WaxJet 400 utilizes MJP technology, enabling smooth surface finishes, high precision, and the use of wax-based materials for casting.

Casting-Minded Design

The printer is designed with casting in mind, featuring a large print bed for easy printing and casting of complex designs.

Directly Castable Material

The printer uses wax-based material, and the casting parameters are the same as those for wax, ensuring compatibility with existing casting processes.

Auto Support Generation

The WaxJet 400 automatically generates support structures, increasing production output and simplifying support removal.

High Precision

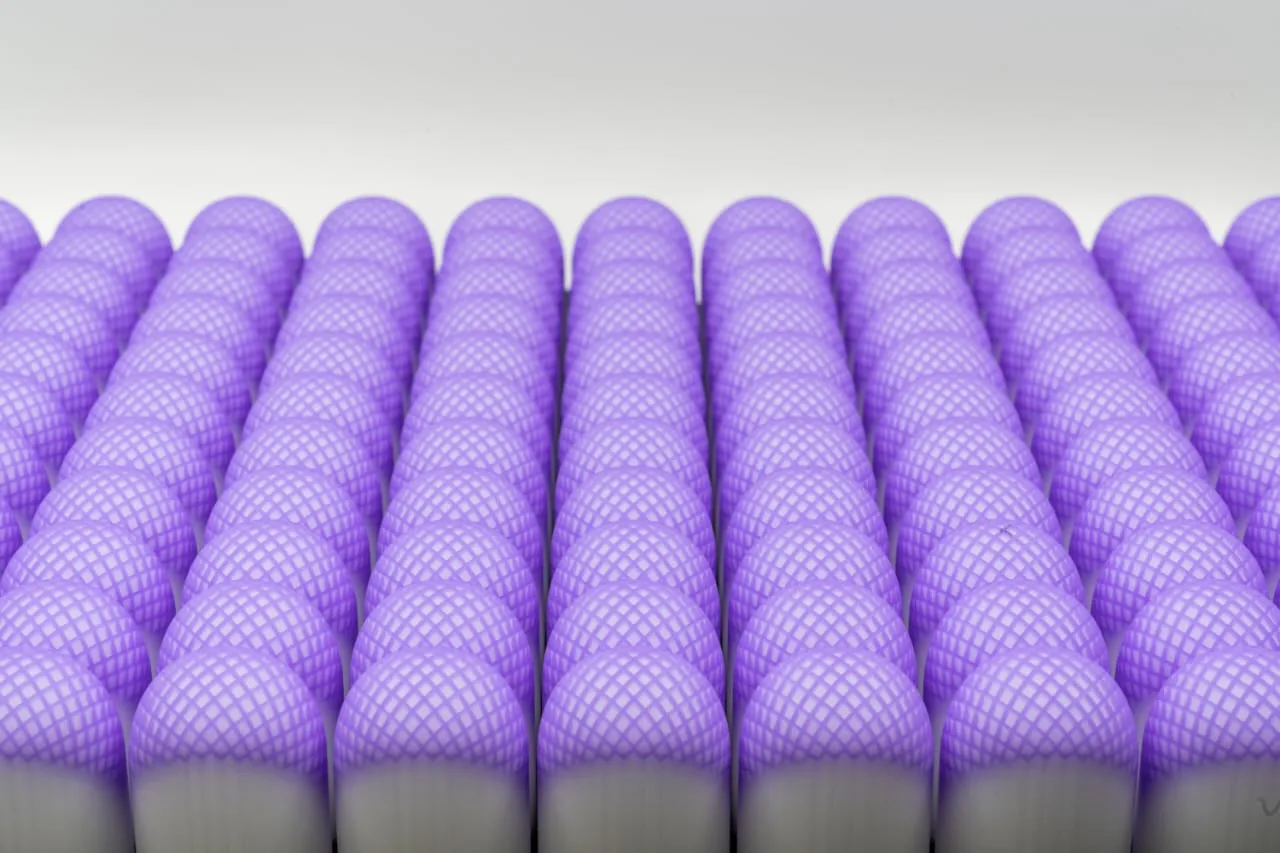

The WaxJet 400 can print layers at a minimum height of 16 microns, ensuring flawless print quality with smooth surface finishes required in precision investment casting industries.

Industrial-Grade Piezoelectric Printhead

The printer features a high-resolution printhead with a printing resolution of 1200 x 1200 x 1600 dpi and an accuracy of ±0.04 mm / 20 mm.

Spacious Build Volume

The printer has a build volume of 289 x 218 x 150 mm, allowing for printing batches of small parts in one go, enhancing efficiency.

User-Friendly Interface

The WaxJet 400 features a 10.1″ color LVDS touchscreen, USB and 10/100/1000 Ethernet connectivity options, and email notifications about its current status.

Proprietary Slicing Software

The printer comes with WaxJetPrint slicing software, which guides the user through the pre-printing process and supports STL and SLC file formats.

Efficient Space Utilization

The WaxJet 400 optimizes the placement of wax patterns on the tree, ensuring efficient space utilization and higher productivity.

Reduced Material Wastage

The digitally printed wax tree models produced by the WaxJet 400 are less likely to break during the production process, reducing material wastage and enhancing efficiency.

Labor Cost Savings

The WaxJet 400 significantly reduces labor costs by automating the process of creating wax patterns and wax tree models, traditionally labor-intensive and time-consuming.

Improved Profitability and Customer Satisfaction

The WaxJet 400 has been shown to improve profitability and customer satisfaction by allowing customers to obtain 1.5 to 2 times more wax patterns than the conventional method, all without compromising on pattern quality.

Sustainable Production Methods

The WaxJet 400 represents a shift towards more efficient, cost-effective, and sustainable production methods in the jewelry manufacturing industry.

Reviews

There are no reviews yet.